Calacatta Gold Marble Countertops and Vanity Tops

This is a decoration projects, product the Calacatta Gold Marble kitchen tops and vanity tops for a villa in Singapore.

In this project, we supply the service of select material, draw drawings, make production plan drawings, production, arrange transportation.

Contents

1 About Calacatta Gold Marble Info

2 Marble Slab Production

3 Slab Cutting Plan

4 Cut to Size

5 Edge Processing5.1 How to Make Ogee Edge

5.2 How to Process Laminated Edge

6 Edge Polishing

7 Quality Inspection

8 Packing

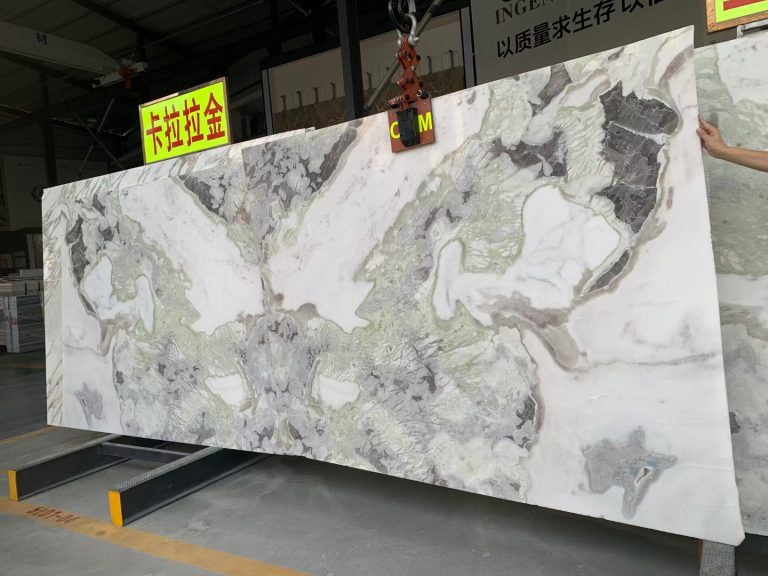

Calacatta Gold Marble Info

Calacatta gold marble is a luxury white marble from Italy, soft white background as warm as jade, with grey and gold veins shuttle across the surface with grace.

It is the most popular luxury white marble, the darling of designer. Bring you the unforgettable beauty. It is widely used in hotel, villa, apartment as kitchen tops, vanity tops, tables, background, wall & floor, stairs and so on.

Many types of Calacatta glod in stock for your selection, have different blocks, the textures are presented in different postures. Below are some for your reference.

Thicker grey veins with gold

- A.Sloping veins

- B.Vertical veins

- C.Multi-stripe

- D.Few veins

Reticulated texture with gold veins

- Veins full of the surface or half of the surface

- Full of gold veins

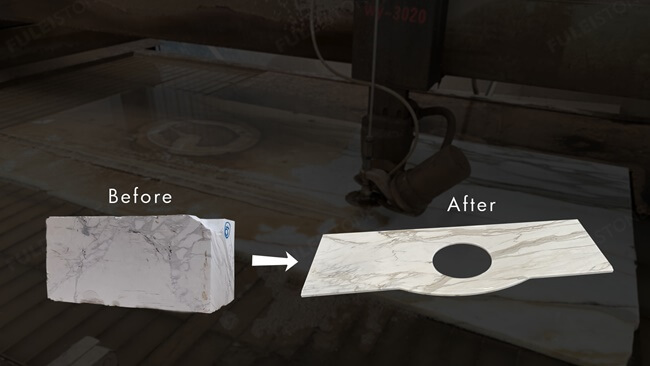

Marble Slab Production

First, we select the most suitable marble block to cut marble slabs for production, according to customer’s requirements like: stone base color, veins direction, size and quality standard, etc.

We Cover the surface of the marble block with fiber mesh and glue, in order to strengthen the block and make it safer for cutting.

Cut the block into slabs by muilt-wire sawing machine, normally we will cut slabs into thicknesses: 1.5cm, 1.8cm, 2cm, 2.3cm, and 3cm.

Slab polishing, both polished and honed surface treatments are available.

All of them are bookmatched finished, and each piece has its own scan pictures, you will know them well and do the cutting plan in the scan image.

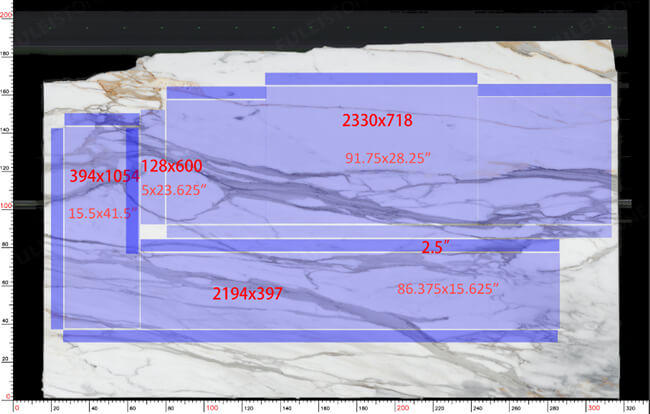

Slab Cutting Plan

We will work out the slab cutting plan for every piece of countertop, backsplash, and laminated edge by dividing the high-resolution scan photos of each slab.

By this way, we draw CAD drawings based on the customer’s draft drawing, then do the cutting plan in the scanned image, and customers will know clearly about every piece looking of their countertops.

Cut to Size

In order to make pieces veins continuously and book-matched as customer’s requirements, we cut the slabs into sizes according to the cutting plans.

About irregular size design, we use a water-jet cutting machine to cut some countertops with arc-shaped edges or other countertops with irregular shapes, make sure the size and the shape is accurate.

Edge Processing

The veins continuously can make the laminated edges looks high end, When we make the veins continuous between countertop and countertop, we also try to take the sticky strip from the edge of the countertop to make the laminated edges veins continuous too.

How to Make Ogee Edge

About Arc-shaped Ogee Edge, we make this Edge by CNC carving machine.

About straight Ogee Edge, we make this Edge by edge modeling machine.

How to Process Laminated Edge

- Clean the fiber mesh at the backside of the marble.

- Rough polishing the surface of laminated edge area, as the rough surface will be combined the exposed and stone better.

- Cover the laminated edge area with AB epoxy.

- Clamp the laminated edges, wait for more than half-hour until the epoxy dry.

- Take off the clamps half hour later.

dge Polishing

First, we using the polishing pads 150#, 500#, 1000#, 2000#, and 6000# to polish the edges one step by one step to make edges shinny. Fine polishing the ogee edges with abrasive paper 3000# and 6000# to remove the scratches on the edges. Repolish the countertop surface if have scratches happened during production.

Quality Inspection

Before packaging, we will check the quality of each piece, if there are some unqualified positions, we will re-make or repair.

Packing

We always take good care about the packing to make it strong enough for shipping, we use three plywood box and wooden bundles together. And also put one piece of artificial marble inside to make it stronger.